- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

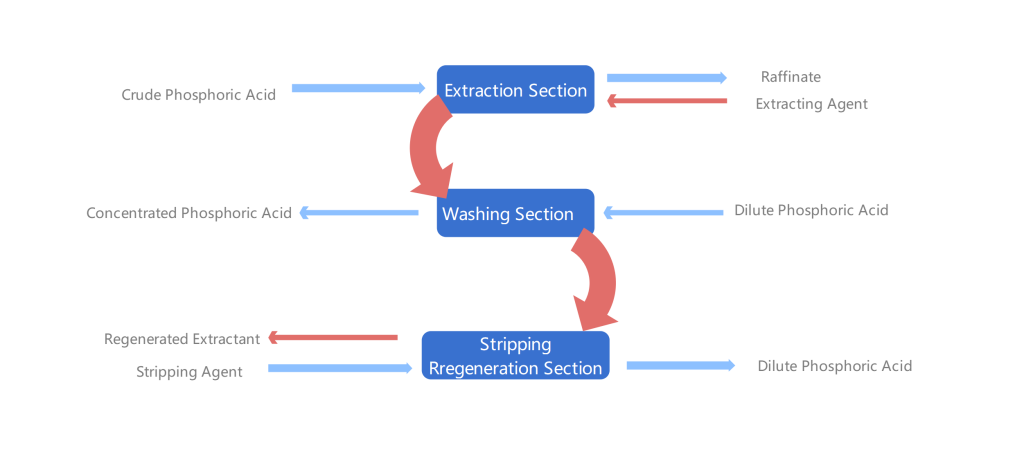

The wet process phosphoric acid process is to decompose phosphate rock powder with inorganic acid to separate crude phosphoric acid, and then purify it to obtain phosphoric acid products. At present, the main purification methods include chemical precipitation, solvent extraction, crystallization and ion exchange. Solvent extraction is widely used in the production of industrial and food grade phosphoric acid due to its advantages such as good separation effect, high recovery rate, and easy automation and continuous production process.

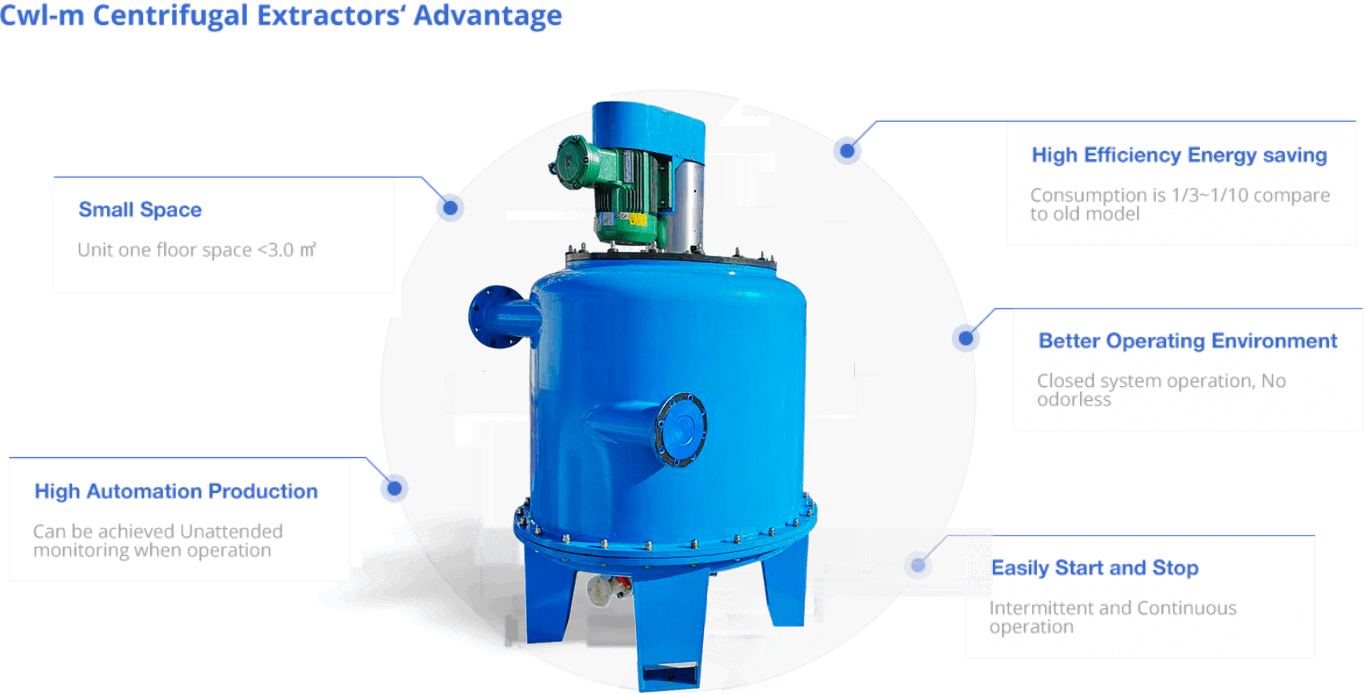

CWL-M series liquid liquid centrifugal extractors have the advantages of low power consumption, good mixing and separation effect, corrosion resistance, and small liquid storage volume. They have been successfully applied in the production of wet process phosphoric acid purification by solution extraction. It can effectively increase production capacity, reduce production costs, improve the production environment, and achieve green and clean production.

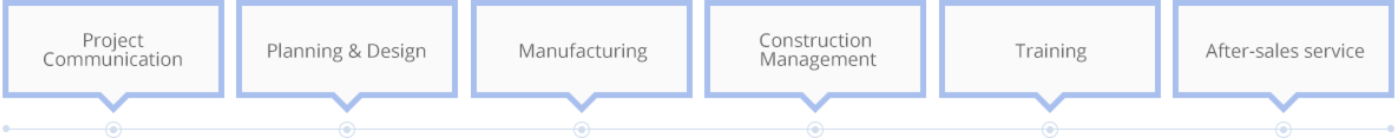

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible