- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

As one of the most in-demand organic acids in the world, citric acid is widely used in food, chemical, pharmaceutical, construction, leather, agriculture, casting, electronics, textile, petroleum, photography, plastics and ceramics and other industrial fields. With the increasingly clear energy conservation advocacy in the national energy policy, most citric acid production enterprises are facing the technological transformation requirement of energy conservation and comprehensive resource utilization, further improving production capacity and quality, reducing energy consumption and pollution, and truly realizing efficient and clean production throughout the entire production cycle.

Compared with other processes, solvent extraction separation technology has the advantages of large processing capacity, good separation effect, high recovery rate, and continuous operation. It does not produce a large amount of waste residue during the extraction process, which is beneficial to environmental protection. It has the following characteristics:

1.Simplified process: The extraction method replaces the calcium salt precipitation method and ion exchange method, eliminating the precipitation, filtration and other processes, reducing labor intensity.

2.High quality: The citric acid product obtained by this process has a high purity, up to 98%, which can meet the application requirements of food and medicine, etc.

3.High yield: The product yield is increased to 98%, and the production capacity is increased by 20%.

4.Green and environmentally friendly: Adopt the new solvent extraction and separation technology, and the COD in the raffinate after citric acid extraction is low. No wastewater or waste residue is generated during the production process, and there is no pollution to the environment, realizing industrial clean production.

Citric acid can react with an extraction agent with the Lewis base group to form a complex, transferring citric acid from the aqueous phase to the organic phase, completing the chemical complex extraction process, separating it from sugars, proteins and other impurities in the fermentation broth, and achieving the purpose of selectively separating citric acid.

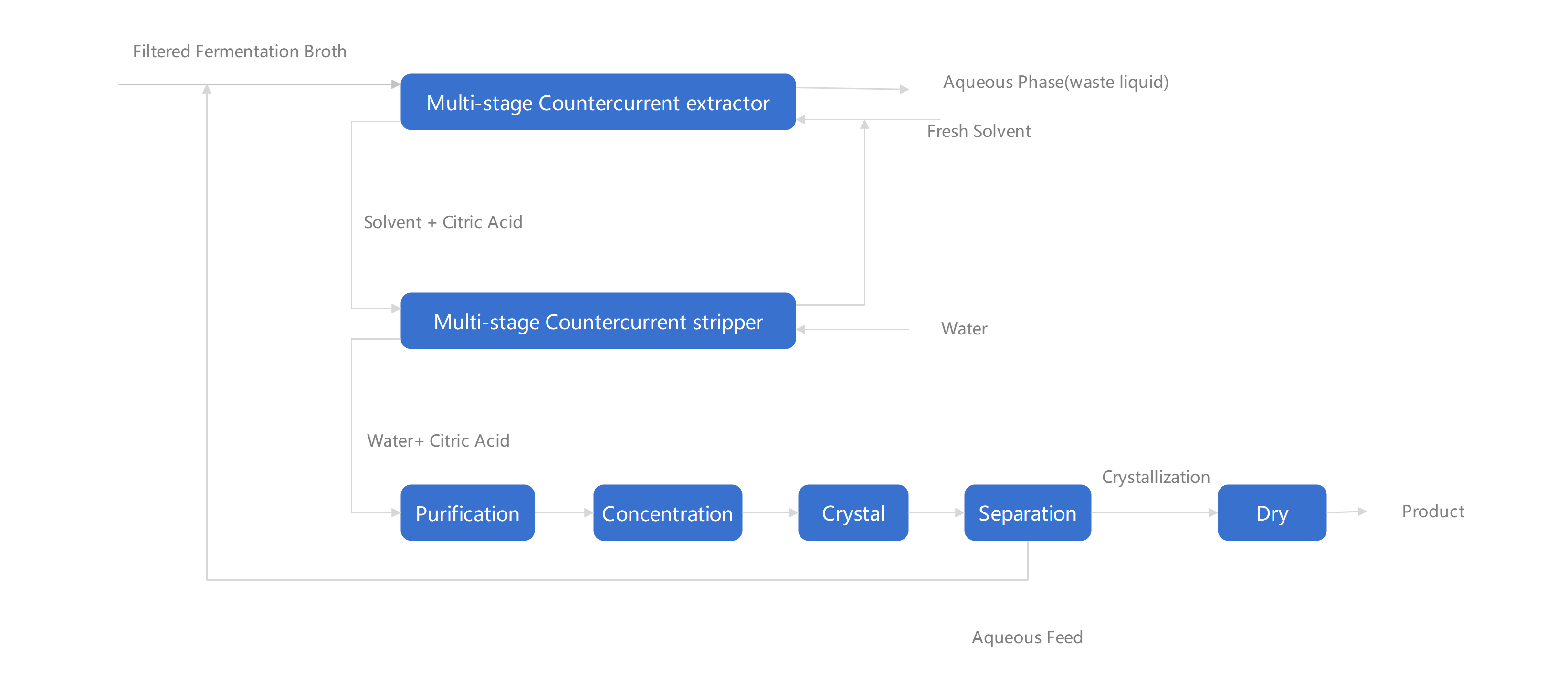

Zhengzhou Tiei Extraction has launched the method for extracting and separating citric acid. The extraction method is simple and effective, and can also achieve environmentally friendly separation and purification of citric acid. Its process flow is mainly as follows:

(1) Preparation of extraction agent. Prepare the extraction solvent and add it in proportion to obtain the extraction solvent of citric acid.

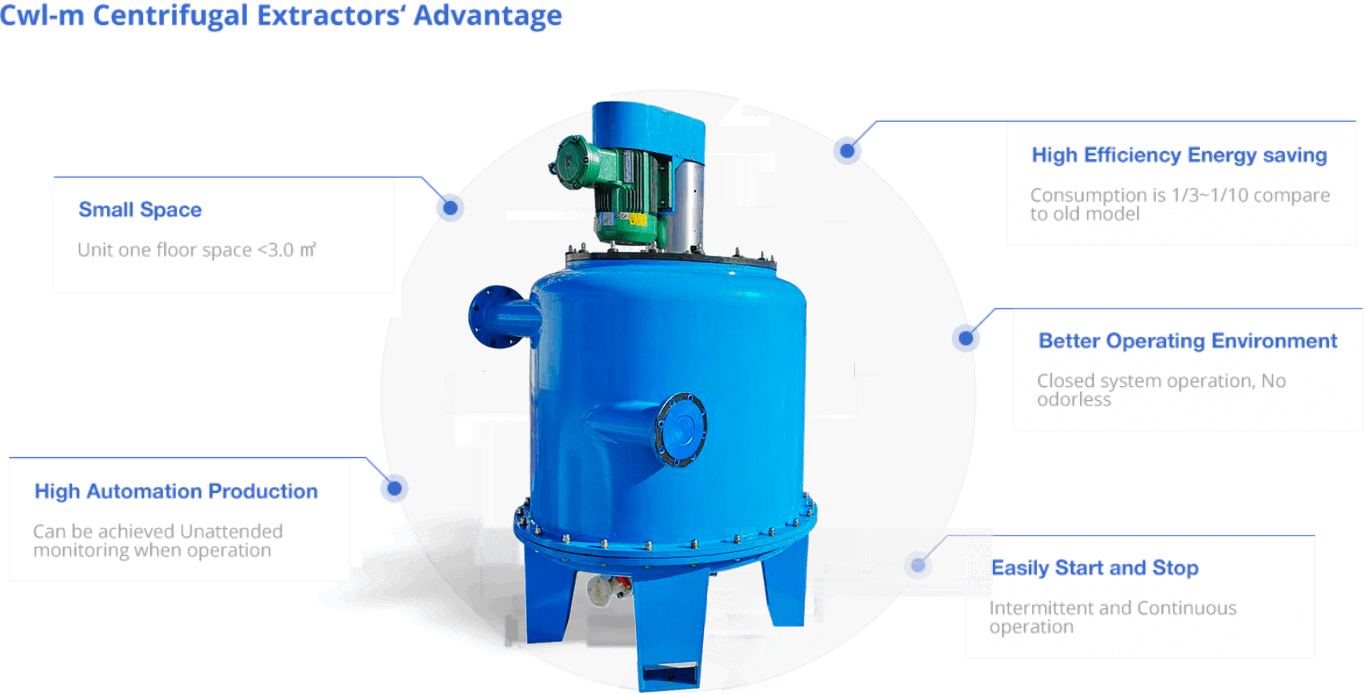

(2) Extraction. Use the prepared organic phase of the extraction agent to carry out countercurrent extraction with the citric acid liquid. The core extraction equipment can be selected from the CWL-M series centrifugal extractor. The detection shows that the citric acid extraction rate is 49% in one time. After countercurrent extraction, the extraction rate can reach 99.3%.

(3) Stripping. The organic phase loaded with citric acid and water are quickly mixed and separated in the CWL-M series centrifugal extractor in proportion. The stripping rate is 78.63% in one time. After countercurrent stripping, the stripping liquid yield is 99.92%.

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible