- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

Lithium precipitation mother liquor generally comes from the residual liquid in the production of lithium carbonate. After the lithium precipitation reaction is completed, the lithium precipitation mother liquor contains a considerable amount of lithium resources. In the process of lithium extraction from brine, lithium resources are not efficiently utilized. The treatment of lithium precipitation mother liquor as sewage will have a huge impact on the environment, and at the same time cause a large loss of lithium in the production of lithium carbonate, reducing economic benefits. The lithium recovery process of lithium precipitation mother liquor is to recycle the lithium in the waste liquid through a series of extraction, separation, concentration and other steps, thereby realizing the recycling of resources.

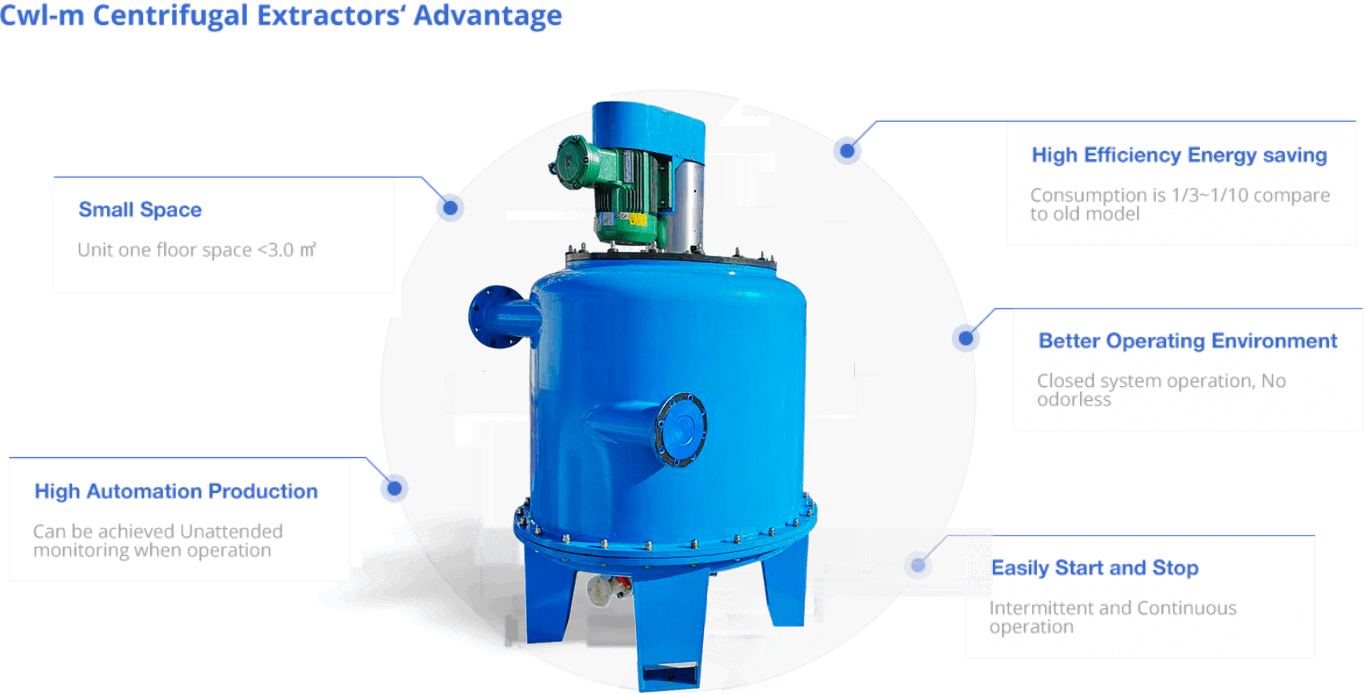

Zhengzhou Tiei Extraction has conducted in-depth research and practice in the field of lithium extraction of lithium precipitation mother liquor, and launched a lithium extraction and recovery process system of lithium-containing solution. The system uses the CWL-M series centrifugal extractor as the core host equipment. After the extraction-washing-stripping section, the lithium resources are finally recovered in the form of lithium chloride. The entire lithium extraction and recovery system has the advantages of high lithium extraction yield, green and pollution-free, simple technical process and low production cost.

At present, Tiei Extraction's lithium extraction and recovery process system for Lithium precipitation mother liquor has been successfully applied to multiple lithium recovery projects of lithium precipitation mother liquor in Qinghai. The equipment operates stably and the application effect is good, which has won praise from many customers.

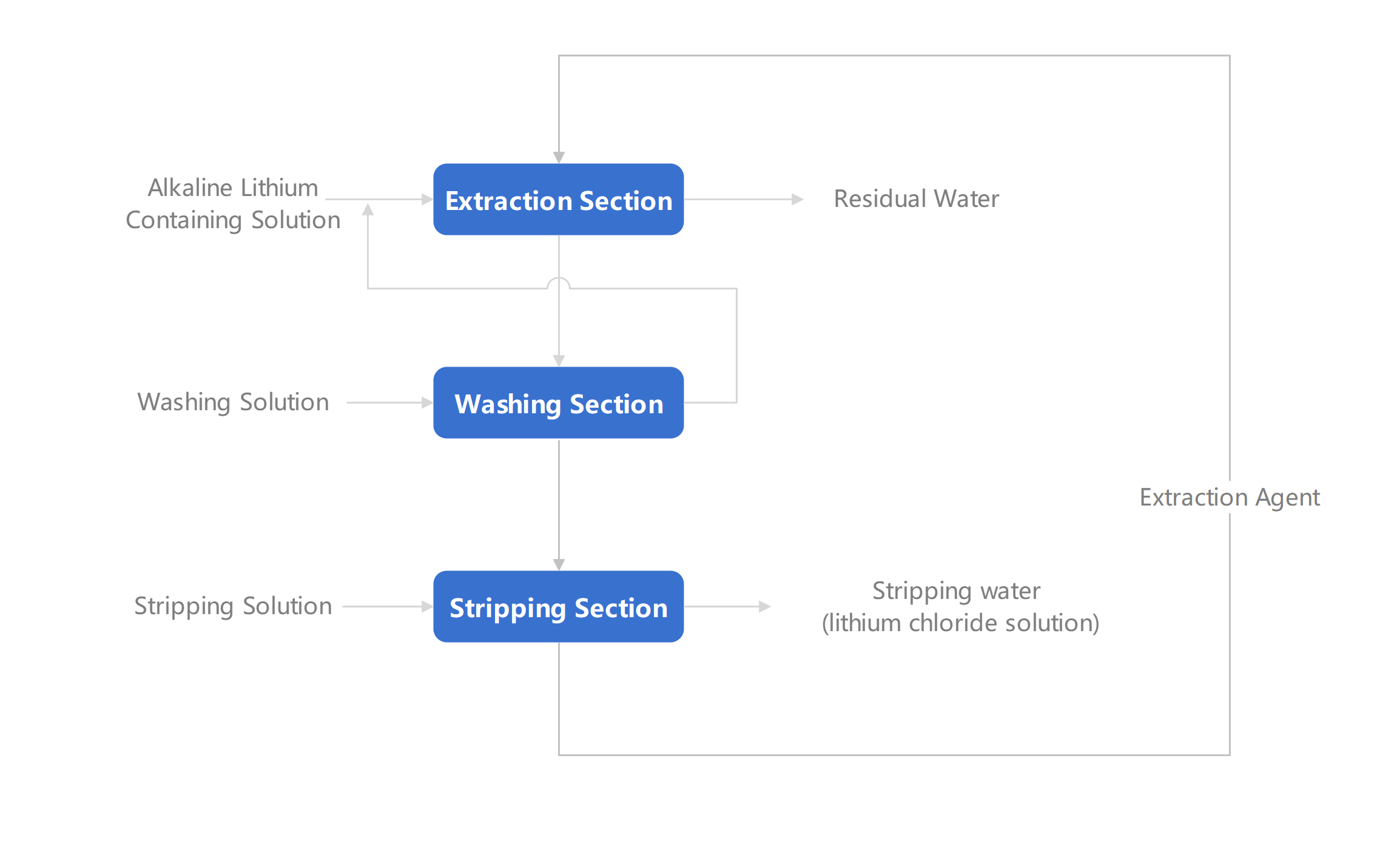

1.The lithium precipitated mother liquor is extracted after adjusting pH. The lithium content in the residual water after extraction is less than 50ppm (can be lowered according to customer requirements).

2.The loaded organic phase enters the washing section. The washing mainly removes the sodium ions in the loaded organic phase.

3.The organic phase after washing enters the stripping section for stripping with hydrochloric acid. The blank organic phase after stripping enters the extraction agent storage tank and continues to be recycled.

4.The aqueous phase after stripping is a high-concentration lithium chloride solution. After oil removal, it enters the lithium precipitation section for direct lithium precipitation.

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible