- About Us

- Equipment

- Solution

- Cases

- News

- Service

- Contact us

Water washing, alkali washing, and acid washing are very common in the chemical production process. The selection of water washing, alkali washing, and acid washing equipment plays an important role in the quality of the product. Therefore, customers need to conduct detailed understanding and inspection when selecting equipment.

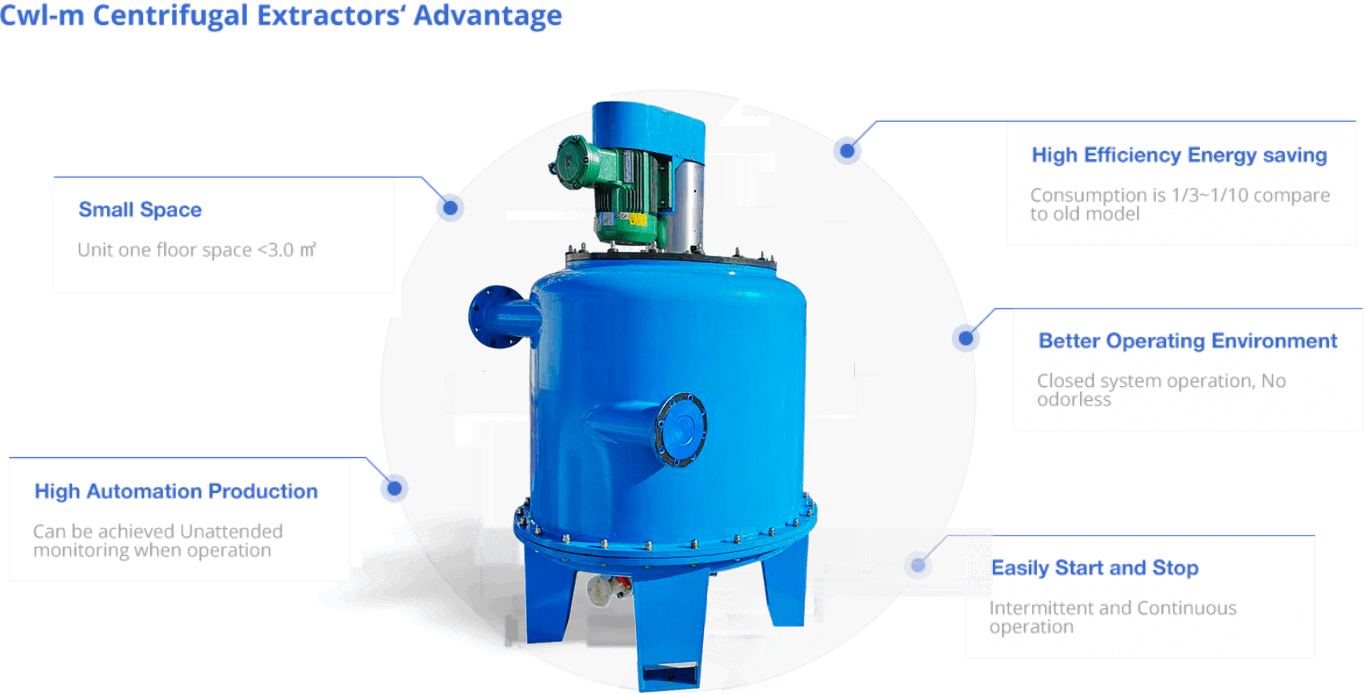

Common water washing, alkali washing, and acid washing equipment include reactors, centrifugal extractors, etc. Traditional reactors were widely used in the past, but with the development of science and technology, reactors can no longer meet the production needs of enterprises. In order to ensure product quality yield, increase output, and meet the needs of continuous production, existing process methods often use multiple centrifugal extracors. Zhengzhou Tiei Extraction CWL-M series new centrifugal extractor can realize continuous extraction of organic phase and aqueous phase, which can completely replace various traditional extraction reactors, reduce solvent consumption, save operating time, reduce energy consumption, reduce three waste. At the same time, it can meet the needs of large-scale production and is a new generation of ideal efficient, green, and continuous extraction equipment.

Our liquid-liquid centrifugal extracors can use water washing, alkali washing, and acid washing:

water washing desalination

alkali washing eluting acid

Naphthalene sulfonic acid extraction

Ethyl acetate extraction

Nitrobenzene extraction

etc

For example, benzene and xylene solution recovery

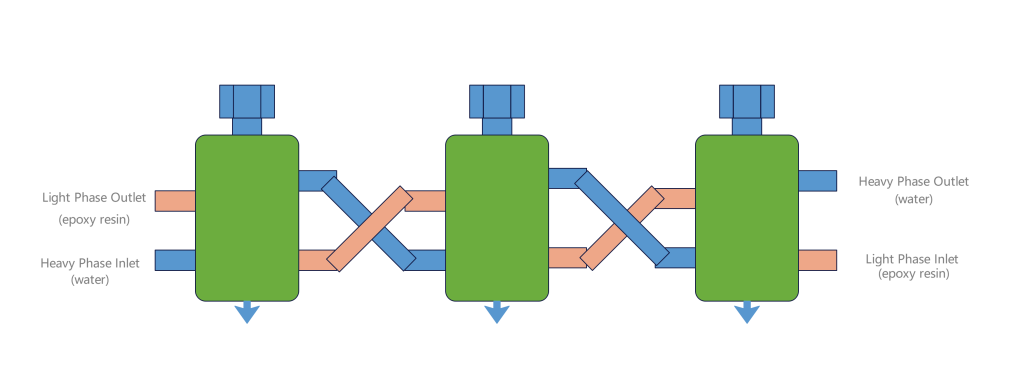

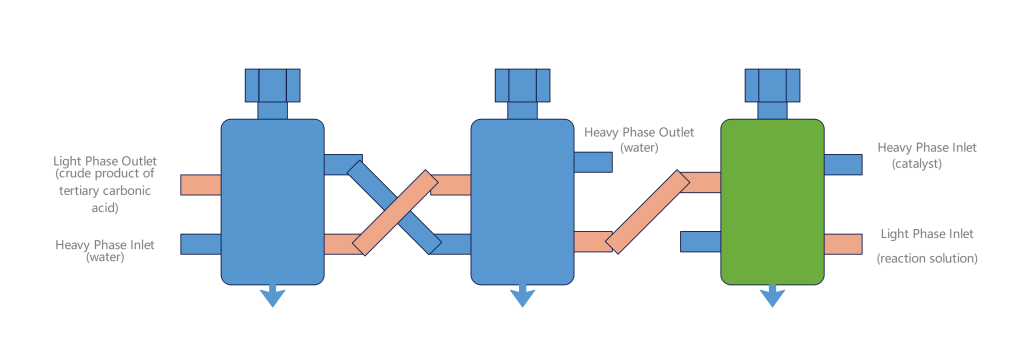

1.Alkali washing eluting acid

In the alkali washing elution acid stage, after the CWL-M centrifugal extractor is turned on, water and sodium hydroxide are injected into the heavy phase port of the CWL-M centrifugal extractor and the heavy phase port of the 1# centrifugal extractor through the metering pump. The acid-containing benzene solution is pumped from the light phase port into the 1#CWL-M centrifugal extractor for countercurrent extraction. In the mixing zone, neutralization reaction between sodium hydroxide and acid in benzene solution, and then the mixed phase enters the high-speed separation zone for rapid separation.

2.Water washing desalination

In the water washing desalination stage, 2# and 3# CWL-M centrifugal extractors are used for two-stage countercurrent water washing desalination. The benzene solution after alkali washing elution acid enters the 2#CWL-M centrifugal extractor and completes the desalting process in the high-speed separation zone.

Note: The number of countercurrent extraction stages can be increased according to the actual situation; it is suitable for separation and recovery of acid-containing organic mixtures that are immiscible with water; the total volume of residual liquid in the cavity is small after the equipment stops running; continuous production can be achieved; all equipment is equipped with static electricity extraction device, made of zirconium material.

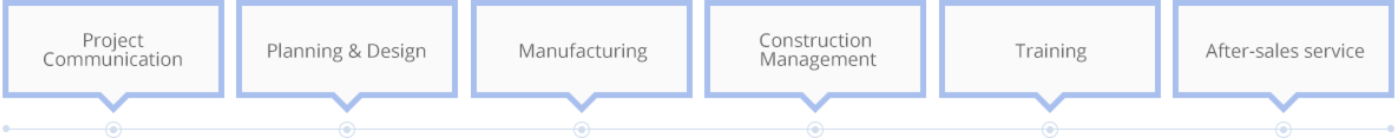

Supporting One-stop service:

Project communication, planning, scheme design, equipment manufacturing ,process operating, and construction management, training and project after-sales service.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible