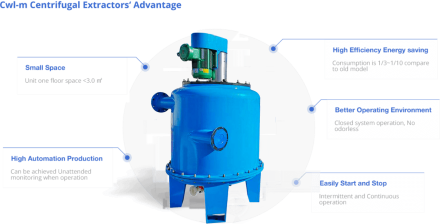

Those who use centrifugal extractors to produce pharmaceutical intermediates know that pharmaceutical intermediates are a branch of refined products, and they are the products of organic synthesis reactions. Most of them require multi-step reactions. After the reaction, most of them need to be extracted with solvents; The traditional production process is to use a reaction kettle. A glass cup is installed under the reaction kettle. After the extractant is added, it is stirred, left standing, and layered. The product can be completely extracted after 2-3 times. The operation of this process is cumbersome, and the production cannot be continuously automated.

If the centrifugal extractor is used in the extraction operation of organic synthesis, it can meet the process requirements after 2-3 stages of extraction, and the extraction operation is completed in one step. For example, in the production of 4,6-dichloropyrimidine, only three stages of extraction tank are needed for the quenched reaction liquid, which makes the production continuous and greatly shortens the production cycle.