1、 Extracting scandium from red mud has very good social benefits

Red mud is a kind of polluting waste residue discharged from the aluminum industry when extracting aluminum oxide. It is called red mud because of its large iron oxide content and similar appearance to red mud. Generally, 1.0~2.0 tons of red mud will be produced for each ton of alumina produced. At present, a large amount of red mud in the world is usually disposed by ocean discharge and land stockpiling. Red mud contains a large amount of strong alkaline chemicals. The traditional treatment method will cause serious pollution to the surrounding water, atmosphere and soil, and the storage yard needs a lot of money and large areas of farmland.

In recent years, the scarcity of resources has become one of the factors limiting the development of China's nonferrous metal industry, and the effective utilization of mineral resources has gradually become a research hotspot. Red mud is rich in a large number of valuable metals. If the red mud stacked in the open air is used, it can not only alleviate the shortage of resources, but also solve the environmental problems caused by red mud stacking.

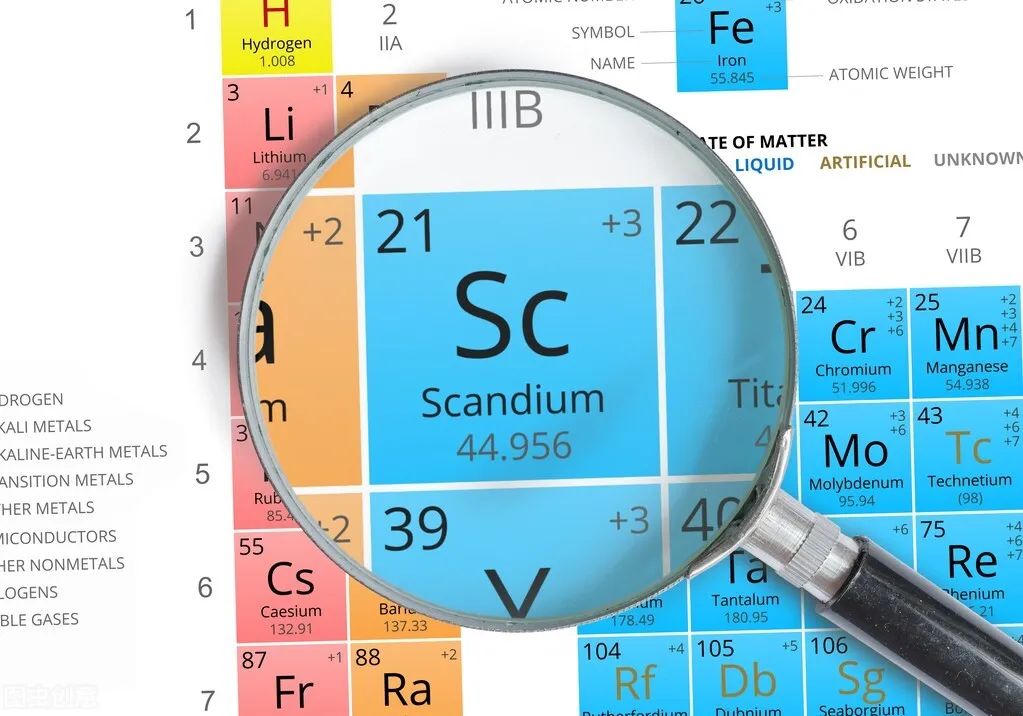

Scandium, element symbol is Sc, atomic number is 21, it is easily soluble in water, can interact with hot water, and easily darkens in air, with the main valence of+3. At present, scandium is widely used in metallurgy, chemical industry, electronics and other industries. As a rare earth element, there are more than 800 kinds of scandium bearing minerals known in nature, but there are relatively few independent scandium mineral resources. Generally, if the scandium content in ore can be 0.002%~0.005%, it can be regarded as an important scandium resource. The scandium content in bauxite generally exceeds 0.004%, while the scandium content in red mud can be enriched to more than 0.01% after aluminum extraction. Moreover, the economic value of scandium in red mud accounts for more than 90% of the value of all rare earth elements.

2、 Recovery of Scandium from Red Mud

At present, the technology of extracting scandium from red mud mainly includes: pretreatment, acid leaching, extraction, washing, stripping, refined extraction and other steps. The reduction smelting method is usually used to treat red mud with high iron content, while the iron content of red mud in China is generally low. The core process of the technical route mainly includes two steps: acid leaching and extraction of scandium.

In the extraction stage, solvent extraction has the advantages of large processing capacity and simple operation. Moreover, with the research and development of various new extraction agents, solvent extraction has been applied more and more, and the extraction effect of scandium in red mud acid extract has also been significantly improved. Common extractants include phosphoric acid extractants (such as P204, P350, P507, Cyanex 272, longquest801, TBP, DDPA, TOPO), 8-HQ, TIA, sulfoxide extractants, etc.), carboxylic acid extractants such as Versatic acid 10, primary amine JMT, neutral phosphorus extractants Cextrant 230, etc. In this extraction stage, centrifugal extraction equipment and mixing clarification tank are often used as the core extraction equipment, while CWL-M series centrifugal extractors have the following obvious advantages:

- High metal extraction rate

- Simple process flow and convenient operation

- The obtained stripping solution has stable quality and can meet different production requirements

- The residual amount of aqueous solvent after treatment is less, which can reduce the treatment pressure of subsequent sections

- The extraction equipment occupies less area and has large processing flexibility