Phosphoric acid wet extraction and purification is a hot topic in the industry. With the rapid development of new energy, the market demand for phosphoric acid is also rising. Therefore, the demand for phosphoric acid extraction, purification technology and equipment is particularly important.

There are many methods for extracting and purifying phosphoric acid. The most widely used one is solvent extraction, that is, hosphoric acid wet extraction. Wet production is to decompose phosphate rock powder with inorganic acid, separate crude phosphoric acid, and then purify it to obtain phosphoric acid products. The domestic wet phosphoric acid purification technology adopts solvent extraction. At present, the most commonly used extractants are mainly fatty alcohols with 4-5 carbon atoms. Representative alcohols include n-butanol and isopentanol. In recent years, the organic solvents that have been widely used in industrial-scale phosphoric acid purification equipment at home and abroad are mainly: methyl isobutyl ketone (MIBK), isopropanol, tributyl phosphate (TBP), n-butanol, methanol, etc.

When choosing solvent extraction for wet phosphoric acid purification, the selected extraction equipment is very important. The extraction equipment and stripping equipment that can be selected mainly include mixer settlers, centrifugal extractors, etc.

1.Mixer settler

The mixer settler generally consists of a mixing tank and a settling tank. A stirring device is usually installed in the mixing tank to increase the mass transfer coefficient and contact area. The advantages of the mixer settler are strong operational reliability, simple scale-up experiments, wide range of use, good pre-separation effect, and the efficiency of the industrial-scale mixer settler can reach more than 90%. The disadvantages are large floor space, large investment, and high operating costs.

2.Centrifugal Extractor

Compared with the mixer settler, the centrifugal extractor can achieve good phase separation and demulsification (i.e., not easy to emulsify), which can fully meet customer needs.

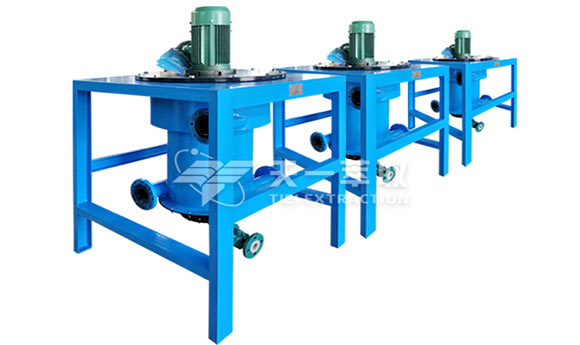

CWL-M centrifugal extractor is a new, efficient and energy-saving liquid-liquid extraction and separation equipment independently developed and produced by Zhengzhou Tiei Extraction Technology Co., Ltd. It can be effectively applied to wet phosphoric acid extraction and purification operations. Compared with traditional mixer settlers and other equipment, centrifugal extractors are essentially different in working principle. Centrifugal extractors rely on centrifugal force to quickly mix and transfer two-phase liquids, with advantages such as large processing capacity, high extraction efficiency and good extraction effect.

The above is a brief introduction to phosphoric acid wet extraction and purification equipment--CWL-M centrifugal extractor. For details about the centrifugal extractor, welcome contact us.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820