Treatment of phenolic wastewater is a pretreatment operation, which is a pretreatment before wastewater treatment. Because phenol-containing wastewater generally has a high concentration, high organic matter content, and high COD, it is very troublesome and costly to discharge it directly according to sewage treatment. Therefore, pretreatment is required to extract organic matter from wastewater, reduce COD, and then carry out subsequent biochemical treatment.

The method for treating phenol-containing wastewater

- Extraction: The pretreated phenol-containing wastewater enters the centrifugal extractor, where it is quickly mixed with the extractant. The phenolic compounds in the aqueous phase enter the extraction phase, and the wastewater enters the biochemical section for subsequent treatment.

- Stripping: The extraction phase enters the stripping section. When sodium hydroxide is used as the stripping agent, the phenols in the extractant are recovered in the form of sodium phenolate salts, and the extractant is recycled and reused.

This process has a high extraction rate for phenols, the extractant can be recycled and reused, and at the same time, it produces a by-product of sodium phenol salt with economic value, which greatly reduces operating costs while ensuring the wastewater treatment effect.

Phenol-containing wastewater treatment equipment

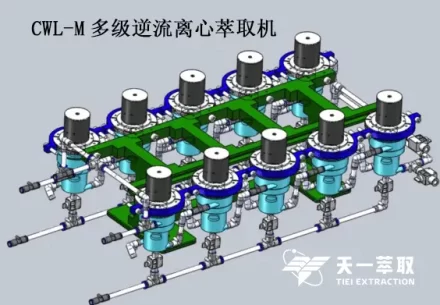

CWL-M centrifugal extractor is a new, efficient and energy-saving liquid liquid extraction and separation equipment independently developed and produced by Zhengzhou Tiei Extraction. Compared with traditional mixer settlers, extraction columns and other equipment, the new centrifugal extractor can separate two immiscible liquids with different densities under the action of centrifugal force, and the separation effect is more efficient.

Performance advantages of CWL-M centrifugal extractor

- The separation effect of the two phases is better under the action of centrifugal force.

- The mass transfer efficiency of the feed liquid is high, and the stage efficiency is also higher.

- The use of less extractant can greatly save the investment cost of the extractant.

- It can be operated intermittently, can be operated alone, and can be operated continuously in countercurrent, which is convenient and simple.

If you would like to know more details, welcome contact us.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820