With the development of technology, lithium has become one of the metal elements with the fastest growing market demand, mainly used in the field of new energy. Lithium resources mainly exist in the lithium mines and salt lakes.

In the production process of lithium carbonate, the lithium precipitated mother liquor contains a considerable amount of lithium resources after the lithium precipitation reaction is completed. Therefore, in the process of extracting lithium, lithium resources are not efficiently utilized. Treating the lithium precipitated mother liquor as sewage will have a huge impact on the environment, and at the same time cause a lot of lithium loss in the production process of lithium carbonate, reducing economic benefits. There are many problems with the existing lithium recovery process of the lithium precipitated mother liquor, and how to achieve efficient and low-cost recovery of the lithium precipitated mother liquor is imminent.

After a large number of experiments, adopted centrifugal extractors to extract lithium from lithium precipitation mother liquor has the advantages of high lithium extraction rate, low power consumption, and large processing capacity. The new technology for extracting and separating lithium/sodium-potassium mixed solutions from lithium precipitation mother liquor in the centrifugal extraction system has good application prospects. First of all, with the growth of lithium resource supply and demand, short-process and efficient lithium recovery in solutions such as lithium battery recovery tail water and precursor synthesis tail water has significant cost advantages. At the same time, compared with traditional evaporation and concentration, the highly selective separation and enrichment of lithium in low-grade lithium raw material leachate has low cost and complete separation of lithium and sodium and potassium (β>1000). It only consumes sulfuric acid and liquid alkali, and does not produce additional waste. It is a green and efficient new process for lithium separation and enrichment.

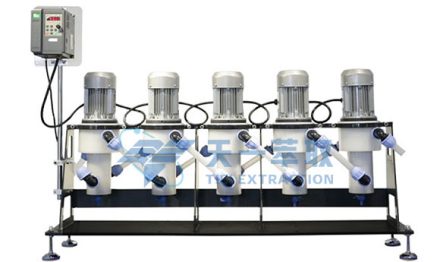

The CWL-M centrifugal extractor developed and produced by Zhengzhou Tiei Extraction Technology Co., Ltd. has been applied to lithium extraction from lithium precipitated mother liquor with remarkable results. The process used is solvent extraction, which uses efficient and new extractants to efficiently separate and extract lithium from alkaline lithium-containing solutions. Solvent extraction technology is an effective technology for separating and extracting various metals from solutions. It has the advantages of high separation efficiency, simple process and equipment, continuous operation, and easy automatic control. It is one of the simple and quick methods to extract and separate lithium from alkaline solutions.

Zhengzhou Tiei Extraction combined centrifugal extraction technology, conducted multiple continuous experiments, and achieved ideal experimental results. The extraction system formula is independently developed, with advanced technology and easy operation. The extractant has a high extraction saturation capacity, good back extraction performance, good physical properties and chemical stability, low corrosion, etc., which is suitable for industrial application.

Lithium extraction technology from lithium precipitation mother liquor has high lithium extraction rate, low power consumption and large processing capacity. If you have related projects to learn about, welcome contact us!

Email: sales@tieiextraction.com

Whatspp: +86 19069612820