Liquid-liquid extraction (also called solvent extraction) was initially utilized in the petroleum

industry beginning in the 1930’s. It has since been utilized in numerous applications including

petroleum, hydrometallurgical, pharmaceutical, and nuclear industries. Liquid-liquid extraction

describes a method for separating components of a solution by utilizing an unequal distribution

of the components between two immiscible liquid phases. In most cases, this process is carried

out by intimately mixing the two immiscible phases, allowing for the selective transfer of

solute(s) from one phase to the other, then allowing the two phases to separate. Typically, one

phase will be an aqueous solution, usually containing the components to be separated, and the

other phase will be an organic solvent, which has a high affinity for some specific components of

the solution. The process is reversible by contacting the solvent loaded with solute(s) with

another immiscible phase that has a higher affinity for the solute than the organic phase. The

transfer of solute from one phase into the solvent phase is referred to as extraction and the

transfer of the solute from the solvent back to the second (aqueous) phase is referred to as

back-extraction or stripping. The two immiscible fluids must be capable of rapidly separating

after being mixed together, and this is primarily a function of the difference in densities between

the two phases.

While limited mass transfer can be completed in a single, batch equilibrium contact of the two

phases, one of the primary advantages of liquid-liquid extraction processes is the ability to

operate in a continuous, multistage countercurrent mode. This allows for very high separation

factors while operating at high processing rates. Countercurrent operation is achieved by

repeating single-stage contacts, with the aqueous and organic streams moving in opposite

directions as shown in Figure

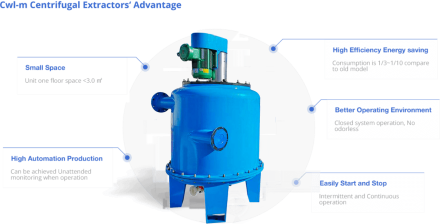

Tiei Extraction design and manufacture of CWL-M serial centrifuges extractors has laboratory scale centrifuges,pilot scale centrifuges and multistage production centrifuges.

Tiei Extraction recommends the CWL-M centrifugal extractor ,with detailed equipment specifications and production capacity, technological process, and equipment characteristics. Also you can view relevant customer cases, extraction Technology solutions, and research trends. Browse all extraction equipment.