The mixer settler is a traditional extraction equipment that appeared earlier. In the mixed separation operation, it mainly relies on gravity for natural separation. The centrifugal extractor is a new, environmentally friendly, green and efficient extraction equipment that has appeared in the market in recent years. The centrifugal extractor relies on centrifugal force for mixed separation. The working principles of the two are essentially different.

Let's compare the Mixer Settler and Centrifugal Extractor and see what differences there are in their working principles, performance, etc.

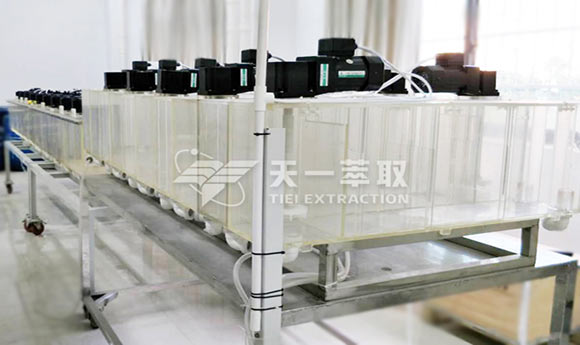

1.Working principle, equipment materials and performance characteristics of Mixer Settler

① Working principle: Gravity is used to separate the two phases. It is divided into the mixing chamber and the clarifying chamber in a ratio of 1:3; the material liquid is mixed and mass transferred in the mixing chamber by the mixer and enters the clarification chamber through the overflow baffle, and the outlet is opened according to the density of the two phases.

② Material design: Generally, it is selected according to the capacity, material and density of the two phases. The common types are 300ML, 1L, and 2L. The materials are: PMMA (acrylic)/PP (polypropylene); 9L material is: PMMA.

③ Performance advantages: stable performance; more flexibility between levels, and lower processing and manufacturing costs.

2.Working principle, equipment materials and performance characteristics of Centrifugal Extractor

① Working principle: Under the action of centrifugal force, the heavier ones move away from the center of the drum and flow toward the drum wall and upward, while the lighter ones do the opposite. Two inlets and two outlets: the heavy phase outlet is at the top, and the light phase outlet is at the bottom.

② Equipment material: The drum is made of perfluorinated material, resistant to strong acid corrosion; the pipeline material is: PVDF (transparent, easy to observe, corrosion-resistant)

③ Performance advantages: small footprint, energy-saving space; high single-stage efficiency, high extraction rate; low power consumption, good energy-saving effect; fully automatic operation, saving manpower.

3.Advantages of Tiei CWL-M Centrifugal Extractors

Traditional centrifugal extractors on the market are prone to corrosion, the bottom seals and bearings are easily damaged, and they are frequently repaired, expensive, and have high power consumption. In response to the problems of traditional centrifugal extractors, Zhengzhou Tiei Extraction has launched the CWL-M new centrifugal extractor after years of scientific research and innovation. The technical advantages of the new CWL centrifugal extractor are:

① Top-hanging structure, low energy consumption, no leakage risk.

② Upgraded corrosion resistance, polymer hybrid materials, such as fluorine and other special materials, can resist corrosion from strong acids, strong alkalis and organic solvents.

③ Lower power consumption: Under the same processing environment, the power consumption of the new equipment is only 1/10~1/3 of that of traditional equipment.

④ A variety of mixing strength options, flexible adaptation to the liquid system.

⑤ Replace the heavy phase weir plate without disassembling the machine, easy to operate and maintain.

⑥ Compact structure, small liquid holding capacity, high extraction efficiency.

The above is the comparison between the mixer settler and the centrifugal extractor. Welcome contact us for more details.

Email: sales@tieiextraction.com