Some liquid systems are corrosive and will cause corrosion damage to the internal parts of the equipment. Therefore, it is necessary to choose extraction equipment made of corrosion-resistant materials. However, many manufacturers produce extraction equipment made of stainless steel and other materials, which cannot play a corrosion-resistant role. So how to choose a centrifugal extractor made of corrosion-resistant materials?

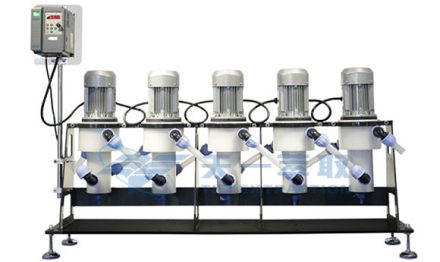

Zhengzhou Tiei Extraction is a professional R&D and production of centrifugal extraction equipment. CWL-M centrifugal extractor has been used in various fields, with good extraction effect. The advantages of the corrosion-resistant system of the centrifugal extractor

- The overall design has no gaps in bonding or welding, and there is no risk of leakage. It can be applied to a variety of systems and various liquid systems.

- The power consumption is extremely low. Under the same performance model, the power consumption of Tiei Extraction's centrifugal extractor is only 1/10 of that of other manufacturers, which is very energy-saving.

- The product design uses a variety of materials, such as polymer composite materials, fluorine materials, 304 stainless steel, 316L stainless steel, etc. These materials have particularly good corrosion resistance, especially polymer composite materials, fluorine materials, etc., which have strong corrosion resistance. The machine uses perfluorinated materials and Hara spraying, which are very resistant to strong acids and alkalis and have excellent anti-penetration properties.

In addition to the above performance advantages, CWL-M centrifugal extractor has many other advantages and features. And Tiei Extraction will first conduct experimental tests on each project to ensure that it can meet customer needs before designing and producing equipment.

We have a customer who purchased the centrifugal extractor resistant to strong acid and alkali. The customer's needs are as follows:

- It needs to be resistant to 20% sulfuric acid and toluene corrosion.

- 100 tons of 20% potassium sulfate and 20 tons of toluene per day, and 100 tons of 20% water contains about 3 tons of materials.

- Centrifugal extractor made of materials resistant to sulfuric acid and toluene corrosion.

Tiei Extraction Engineers communicated with the customer in detail and developed a relevant plan for the customer. When choosing a corrosion-resistant centrifugal extractor, it is necessary to comprehensively consider factors such as the specific characteristics of the feed liquid, the degree of corrosion, the processing volume, and the separation requirements to ensure that the appropriate equipment is selected.

If you want to choose extraction equipment with good corrosion resistance and good extraction effect, welcome to consult us.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820