With the increasing demand for copper due to the development of the market economy, a large amount of copper-containing waste residue will be generated during the production and processing process, including the etching liquid generated during the production of circuit boards. The etching liquid contains metallic copper. If it is directly treated and discharged, it will be a waste of resources and a pollution to the environment. Zhengzhou Tiei Extraction Technology Co., Ltd. has conducted a large number of experiments on the copper extraction project of circuit board etching liquid. The copper in the etching liquid is extracted by the CWL-M centrifugal extractor, and the effect is remarkable. The following is a detailed explanation of how to extract copper from circuit board etching liquid by centrifugal extractor.

The etching solution copper extraction equipment uses the centrifugal extractor, and the process adopts solvent extraction, which has the advantages of good selectivity and high metal recovery rate. At the same time, this technology has been widely used in the field of hydrometallurgy.

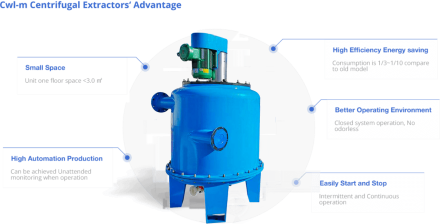

Zhengzhou Tiei Extraction used the CWL50-M experimental centrifugal extractor when conducting a small scale experiment to extract copper from circuit board etching solution. This equipment is a small scale centrifugal extractor, mainly used for laboratory small scale experiments.

At present, the main extractants for copper extraction are diketones, oximes, alcohols, triamines, esters and their compounds. After selecting the extractant, the aqueous feed and the extractant are fed into the extractor at a certain ratio. Countercurrent extraction is adopted, and the liquid and the extractant are quickly mixed and separated by mass transfer in the equipment. The loaded extractant after extraction is fed with a stripping agent of a certain concentration at a certain ratio, and countercurrent extraction is adopted to observe the stripping effect.

The experimental data show that after the CWL50-M centrifugal extractor performs a series of process operations such as extraction and stripping on the circuit board etching liquid, the copper in the waste liquid can be extracted well, at the same time, the amount of extractant used can be greatly reduced, the extraction efficiency can be improved, and the comprehensive investment cost can be reduced.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820