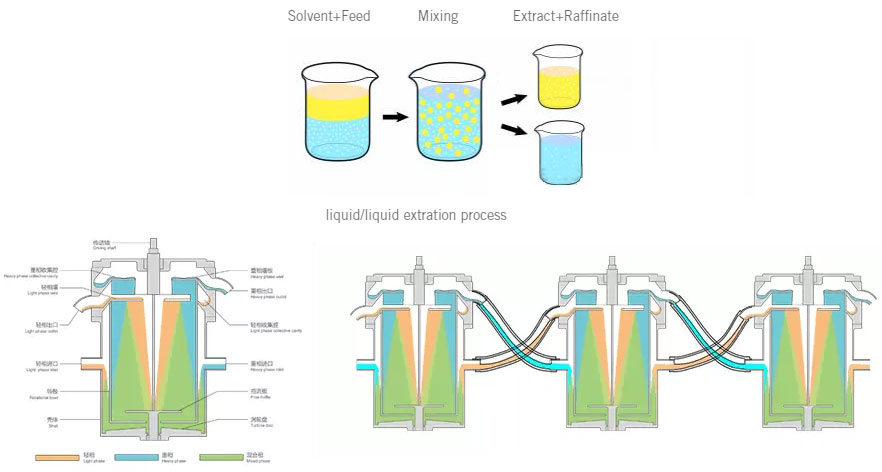

A centrifugal extractor—also known as a centrifugal contactor or annular centrifugal contactor—uses the rotation of the rotor inside a centrifuge to mix two immiscible liquids outside the rotor and to separate the liquids in the field of gravity inside the rotor. This way, a centrifugal extractor generates a continuous extraction from one liquid phase (fermentation broth) into another liquid phase (organic solvent).

Centrifugal contactors are classed as stage-wise or equilibrium contactors because, like mixer-settlers, they manifest a step concentration profile as the aqueous and solvent phases pass from stage to stage. Also, like mixer-settlers, they consist of mixing and phase separation compartments. However, phase separation occurs under the action of centrifugal, rather than gravitational forces, which leads to more compact processing units than mixer-settlers.

Centrifugal contactors are classed as stage-wise or equilibrium contactors because, like mixer-settlers, they manifest a step concentration profile as the aqueous and solvent phases pass from stage to stage. Also, like mixer-settlers, they consist of mixing and phase separation compartments. However, phase separation occurs under the action of centrifugal, rather than gravitational forces, which leads to more compact processing units than mixer-settlers.

Various designs of centrifugal contactor have been developed and they are used extensively for small-scale process development tests. Their compact size makes them ideal for processing solutions containing high concentrations of fissile material. In addition, their compact size also makes them amenable to modular processing unit concepts, such as the Modular Caustic Side Solvent Extraction Unit currently being used to separate cesium from radioactive wastes stored.

The centrifugal contactors receiving most recent attention have integral mixing and phase separation compartments and are more accurately referred to as annular centrifugal contactors. The mixing compartment consists of an annulus bound by the outer housing and an internal rotor bowl that spins at several thousand revolutions per minute. The two liquid phases enter the annulus and are mixed as a result of the shear forces set up by the rotating rotor and the bottom vanes. The mixed phase is drawn from the annulus, between the rotor base and housing and into the rotor bowl. The phases separate as a result of the centrifugal forces and exit the rotor bowl over their respective weirs. Banks of centrifugal contactors are connected together in a similar manner as mixer-settlers to permit counter-current flow.

Residence time in the mixing annulus is very short, of the order of seconds. However, the turbulent energy is sufficiently high that very small drops (fractions of a millimeter) are formed with a high interfacial area that provides for efficient mass transfer. Nonetheless, centrifugal contactors are generally not ideal for liquid-liquid systems exhibiting slow interfacial mass transfer. Wrong-phase entrainment is again a measure of hydraulic performance and Arm has shown entrainment first decreases and then increases with increasing rotor speed. This phenomenon is indicative of how mixing intensity and phase separation performance are related by the rotor speed. The larger drops formed at low rotor speeds are easier to separate, but this is counteracted by the fact that phase separation improves with increasing rotor speed. As the rotor speed increases, the drops become smaller and less easy to separate. Wrong-phase entrainment also increases with increasing flow rate because the mixed phase has less time to separate. Therefore, there is an optimum rotor speed and flow rate to minimize wrong-phase entrainment.

Tiei Extraction design and manufacture of CWL-M serial centrifuges extractors has laboratory scale centrifuges, pilot scale centrifuges and multistage production centrifuges.

Tiei Extraction focus on being Liquid–Liquid extraction Mixing And Separation Solution Provider.