Glycolic acid is a natural compound with both hydroxyl and carboxylic acid groups, which is found in sugarcane, beets, grapes and fruits. As an important fine chemical, glycolic acid is also widely used in high-end polymer applications such as chemical cleaning, pharmaceutical synthesis, surgical sutures and biodegradable plastics. Glycolic acid can be synthesized by chemical methods such as hydrolysis of chloroacetic acid or hydroxyacetonitrile, or it can be synthesized by conversion of special bacteria or enzyme reactions. Precipitation is the most commonly used method in the separation and purification of glycolic acid. In recent years, the significant role of liquid liquid centrifugal extraction in the efficient purification of glycolic acid aqueous solutions has received increasing attention. Through the comprehensive use of new liquid liquid centrifugal extraction technology + traditional processes such as precipitation method, high-purity glycolic acid solids can be obtained for high-end applications such as medicine and polymers, which is expected to reshape the glycolic acid industry.

Liquid liquid centrifugal extraction is often used to purify target solutes in aqueous solutions. The basic operation process of liquid liquid extraction is to add an organic reagent (also called an extractant) that is immiscible with water to the aqueous solution, stir and mix evenly, and then go through the first oil-water separation to separate it into an organic phase (also called an oil phase) and an aqueous phase. Generally, the two phases have a clear interface and can be separated by phase separation. The target is enriched in the oil phase and separated from impurities in the water to be purified. Under certain conditions, the oil phase (also called the loading phase) containing the target obtained by phase separation is then mixed evenly with a specific reagent (also called a stripping agent, such as pure water). After the second oil-water separation, a high-purity target solution (such as a target aqueous solution) is obtained, and the extractant is regenerated at the same time. The regenerated extractant can be returned for target extraction.

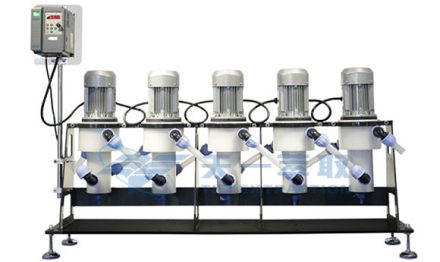

The key to liquid liquid extraction is to choose a suitable extractant. An ideal extractant has high selectivity and solubility for the target substance in the aqueous solution, so that the ratio of the concentration of the target substance in the extractant to that in water (distribution coefficient) is as high as possible, while the ratio of the concentration of impurities in the extractant to that in water is as low as possible, and the solubility of the extractant in water is as low as possible. The liquid liquid centrifugal extractor is an ideal equipment for liquid liquid extraction. The centrifugal extractor combines mixing and liquid separation. It processes a large amount of liquid per unit time. A liquid-liquid extraction operation can be completed in a few seconds at the shortest, and a single equipment has a small liquid holding capacity (that is, a single equipment requires very little extractant). It is especially suitable for some liquid liquid separation processes that are significantly affected by dynamics or have high extractant prices.

When the above liquid liquid extraction principle is applied to the purification of glycolic acid aqueous solution, it is found that the octanol-water partition coefficient of glycolic acid is -1.11, which means that glycolic acid is more likely to dissolve in water than common solvents such as alcohol solvents. The partition coefficient of glycolic acid is very low, and the partition coefficient of commonly used solvent glycolic acid is much lower than 1/2, which means that under ideal conditions, the yield of glycolic acid in a single extraction is much lower than 1/3. The literature also concludes that there is no commonly used solvent that can effectively extract glycolic acid from glycolic acid aqueous solution.

But chemical extraction can be considered. In most cases, the extractant extracts the target substance by physical force, and no chemical reaction occurs during the extraction process. This most commonly used extraction method can also be called physical extraction. Chemical extraction refers to the process in which the extractant can react chemically with the target substance, making it easier to separate the target substance from the original system. Chemical extraction has been widely used in industry in the separation of organic acids such as lactic acid, citric acid, and succinic acid from water. Tiei Extraction's CWL-M series centrifugal extractor is well received in these industries. Chemical extraction can significantly improve the efficiency of separating glycolic acid from glycolic acid aqueous solution, and the glycolic acid distribution coefficient is greatly increased. For example, when trioctylamine (TOA) is used as a chemical extractant and dichloromethane or n-decanol is used as a solvent, the glycolic acid distribution coefficient can be as high as 12, that is, under ideal conditions, the single extraction glycolic acid yield is as high as 92%. Stripping is also relatively simple. At a slightly higher temperature, the stripping effect of pure water is better.

In general, chemical extraction is ideal for separating and purifying glycolic acid from glycolic acid aqueous solution, and is suitable for industrial application, which is expected to solve the current separation and purification problems in the glycolic acid industry. In this process, Tiei Extraction's CWL-M series centrifugal extractor will continue to perform beyond the expectations of customers and the industry, and help the glycolic acid industry move towards a future of high-quality development.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820