Boron is an essential micronutrient for plants and animals. Boron and its compounds have many special properties, such as light weight, flame retardancy, heat resistance, wear resistance, high hardness, high strength and catalysis, making them important basic raw materials for various industries. They are mainly used in metallurgy, light industry, chemical industry, nuclear industry, agriculture, high-tech materials and other fields. Boron is widely present in boron ores, mainly in the form of borates. With the reduction of boron mineral resources, research on the removal or separation of boron from boron-containing water resources such as seawater and salar birne has gradually attracted widespread attention.

What is a Centrifugal Extractor

Centrifugal extractor is one of the most promising technologies for this purpose. This advanced equipment, such as the Zhengzhou Tiewei CWL-M Centrifugal Extractor, plays a key role in improving the efficiency and effectiveness of extracting boron from ores and other sources.

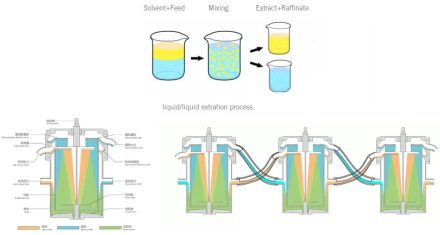

Centrifugal extractor is a type of liquid-liquid extraction equipment that uses centrifugal force to separate components of a mixture based on their density differences. It is particularly valuable in processes where two immiscible liquids (usually water and an organic solvent) are involved, and the target material (such as boron) needs to be selectively transferred from one phase to another.

In boron extraction, the centrifugal extractor enables high-speed separation of boron-containing compounds from aqueous solutions into an organic phase, which is then subjected to further recovery processes. The design of the centrifugal extractor ensures minimal energy consumption, reduced solvent usage, and a high degree of separation efficiency

Boron Extraction Process with Centrifugal Extractor

The typical boron extraction process involves several stages, where centrifugal extractor can be effectively applied:

1.Preparation of Feed Solution: The raw material (usually boron-rich ore or a brine solution) is first subjected to leaching to dissolve the boron compounds into an aqueous solution. The leachate may contain boron in various forms such as boric acid or borates.

2.Liquid-Liquid Extraction: The leachate is then fed into the centrifugal extractor, where it is mixed with an organic solvent that selectively binds to the boron compounds. As the mixture rotates within the extractor, centrifugal force pushes the heavier aqueous phase to the outer edges, while the organic phase containing the boron compounds moves towards the center. This phase separation ensures efficient extraction.

3.Phase Separation and Recovery: After extraction, the organic phase, now enriched with boron, is separated from the aqueous phase. The organic phase is then processed further to recover the boron, typically through stripping, where the boron is transferred back into the aqueous phase for subsequent processing and purification.

4.Regeneration of Solvent: One of the major advantages of using centrifugal extractors in boron extraction is their ability to regenerate the organic solvent. After the boron has been stripped from the organic phase, the solvent can be reused, reducing operational costs and environmental impact.

Advantages of CWL-M Centrifugal Extractor

The Zhengzhou Tiei CWL-M Centrifugal Extractor offers several advantages when applied to boron extraction and recovery:

High Efficiency: Due to its design, the CWL-M extractor provides superior phase separation and high extraction rates, which leads to higher yields of boron.

Reduced Solvent Consumption: The centrifugal extractor reduces solvent consumption compared to conventional extraction methods, which is both cost-effective and environmentally friendly.

Energy Savings: The centrifugal force generated within the extractor minimizes the need for additional mechanical agitation, thereby reducing energy costs.

Compact Design: The compact size of the CWL-M extractor makes it ideal for space-constrained operations and scalable for large-scale industrial processes.

Versatility: The CWL-M is suitable for a wide range of applications, including different feed solutions, making it adaptable to various boron extraction processes.

Centrifugal extraction is a method for recovering boron from boron-containing solutions. It has the advantages of short process flow and low production cost. It is less restricted by the boric acid content in the solution and can be used for extraction in a wide concentration range. Therefore, it has good application prospects. Zhengzhou Tiei Extraction CWL-M series centrifugal extractor has the characteristics of high recovery rate, high purity and low cost. They can carry out continuous centrifugal extraction processes and can stably and efficiently meet the needs of large-scale production.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820