Traditional energy sources such as fossil fuels, oil, coal and methane are non-renewable energy sources. In order to meet energy needs, biodiesel is an ideal alternative to traditional fuels because of its renewable, non-toxic and environmentally friendly characteristics. Biodiesel is a long-chain fatty acid ester produced by the transesterification reaction of low-carbon alcohols (such as methanol) and triglycerides under the action of a catalyst. It has high yield and good performance.

When using the centrifugal extractor to produce biodiesel, soybean oil and methanol containing an alkaline catalyst (molar ratio of 1:5.1) are input into the centrifugal extractor for mixed separation at 0.26MPa, 80℃, 3600rpm, and 2min. After about five stages of extraction, the diesel yield can reach 95%; sunflower oil and 1wt.% sodium methoxide solution are input into the centrifugal extractor at a ratio of 4:1, and biodiesel is continuously produced at 60℃ and 2400rpm, with a yield of 96%.

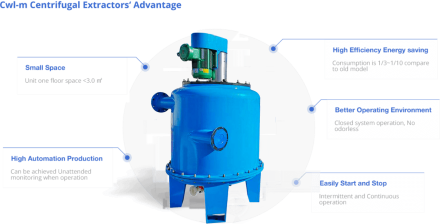

Centrifugal extractor can be used in industrial-scale transesterification to produce biodiesel. In the production process of biodiesel, centrifugal extractor can effectively improve the separation degree of glycerol and biodiesel, thereby improving product quality. Centrifugal extractor has demonstrated multifunctional advantages in biodiesel extraction, such as high efficiency, energy saving, environmental protection, etc., and are an indispensable key equipment in biodiesel.

Welcome contact us for more details about centrifugal extractor.

Email: sales@tieiextraction.com

Whatsapp: +86 19069612820