At present, the extraction method of amino acids is mainly conventional liquid-liquid extraction. Liquid-liquid extraction method is a separation method that adds a selected solvent that is immiscible (or slightly miscible) with the liquid mixture, and uses the different solubility of its components in the solvent to achieve the purpose of separation or extraction. In this process, the distribution coefficient of amino acids in the aqueous phase and the organic phase determines the ease of transferring the extracted components into the organic phase.

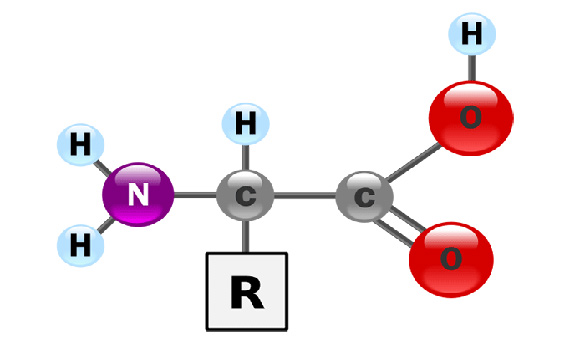

Amino acids include, but are not limited to, alanine, methionine, threonine, lysine, etc. These amino acids have important physiological functions and nutritional value in organisms, and therefore are widely used in food, medicine, cosmetics and other fields.

The specific process flow of amino acid extraction is as follows:

1.Extraction: Mix the amino acid fermentation broth obtained through fermentation or enzymatic conversion with an organic solvent to transfer the amino acids from the aqueous phase to the organic phase. In this process, we use Tiei Extraction CWL-M centrifugal extractor to extract and separate the mixed liquid, which has high mass transfer efficiency and good extraction effect. Then the mixed liquid is evaporated and concentrated to remove water, and an organic solvent containing amino acids is obtained.

2.Stripping: Mix the organic solvent containing amino acids with the alkaline/acidic solution to obtain an amino acid salt solution. The organic phase and the amino acid brine are separated by the CWL-M centrifugal extractor. The organic solvent after separating the amino acids can be returned to the extraction section for recycling.

The method of centrifugal extraction to separate amino acids has many advantages. First, the process route is short and easy to operate. Compared with other separation methods, the operating steps of the liquid-liquid centrifugal extraction method are relatively simple, the equipment requirements are relatively low, and it is easy to implement industrial production. Secondly, the amino acid obtained has high purity and high product yield. By selecting appropriate solvents and operating conditions, amino acids can be effectively separated and purified to obtain high-purity products. In addition, the environmental pollution is small, and the complex operation process in the traditional amino acid production process is avoided. This method can reduce the use of organic solvents and waste generation, reducing the impact on the environment.

However, this method also has some limitations. For example, safety issues such as toxicity and flammability need to be considered when selecting solvents, and appropriate safety measures need to be taken when handling organic solvents. In addition, there may be problems with incomplete extraction or more impurities in the extraction product during the extraction process. It is necessary to further optimize the process conditions and select an appropriate separation method.

In summary, the liquid-liquid centrifugal extraction method is an effective amino acid extraction process. It has the advantages of short process route, easy operation, high purity of amino acids obtained, high product yield, and low environmental pollution. In practical applications, it is necessary to select appropriate solvents and operating conditions according to specific circumstances, and combine them with other separation methods for further purification to obtain high-quality amino acid products.