The TIEI Extraction has decades of experience designing and supplying liquid-liquid extraction / solvent extraction equipment. Our LLE / SX Centrifuge Extractor are engineered to fulfill the challenging purification requirements that exist in the alternative energy, biobased & renewable chemicals, flavor and fragrance, metals and mining, petrochemical and hydrocarbons, pharmaceuticals, polymers, and specialty chemicals industries. Tiei Extraction design and manufacture of CWL-M serial centrifuges extractors has laboratory scale centrifuges, pilot scale centrifuges and multistage production centrifuges.

We do more than sell extraction equipment; we supply solutions to difficult mixing and separation challenges. Liquid-liquid extraction has become the standard for certain processes, such as the recovery of high boiling organics or non-volatile inorganics from dilute aqueous streams.

Tiei Extraction focus on being Mixing And Separation Solution Provider.We continue the relationship with our customers after installation and startup. Our team consists of professional, skilled, and highly qualified technicians and engineers who can provide on-site mechanical and process-related support.

Reasons to Use Liquid-Liquid Extraction / Solvent Extraction

Recovery of water soluble components from immiscible organic streams

A complex distillation sequence is required

Processing of azeotropic and close boiling components

The component of interest is prone to thermal degradation or is non-volatile

Energy requirements of distillation are prohibitive

LLE / SX can be avoided if it is more economical to separate chemicals of interest via distillation. However, there are other situations where liquid-liquid extraction / solvent extraction should be considered.

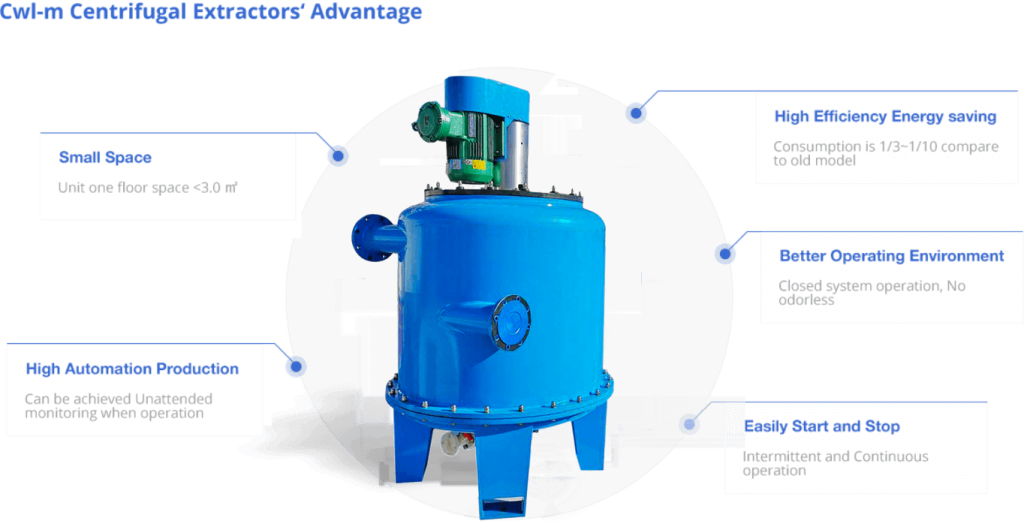

Liquid-Liquid Extraction Features:

01 Simple and Stable structure

02 Energy Saving

03 Corrosion resistant

04 Efficiently Good mixing and separation

05 Easy replacement of heavy phase weir

06 Small liquid storage

07 Continuous Automatic operation

Industry Applications

Complete System Design

Mixing and Mass Transfer Process:

Light and heavy phases of solution enter into the inside of shell seperated from two feed inlets,then rapidly mixing and separated

Separation Process: Under the centrifugal force,the mixed liquid enter into the rotational bowl,the heavy liquid is away from the bowl center,towards to the wall of bowl, while the lighter liquid is towards to the bowl center. Claified liquid enter into the collecting chamber throght respective weirs and discharged from seperated outlets

Security

- Rotational drum is made by polymer hybrid composite material

Can meet the strength required for equipment operation

Solved problem of corrosion of equipment by acid, alkali and solvent - Conductive static electricity

Equipped with static conductive device - Inside Isolated area

Simple equipment maintenance - Avoid high temperature ignition of extractant caused by bearing damage

Optional bearing temperature, vibration, speed, current and other online detection devices

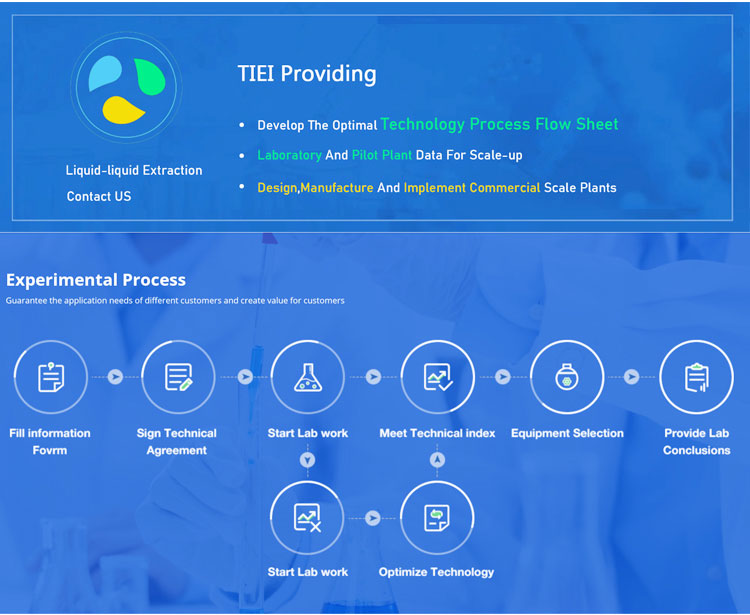

Process Development: Laboratory Testing to Pilot Testing to Commercialization

Nearly all extraction projects require pilot testing to provide the basis for commercial process design and a process performance guarantee. Extraction involves complex chemical phenomena at the liquid-liquid interface which is very difficult to model to allow for commercial scale process design. When conducting an extraction pilot test, it is highly preferable to use actual plant feed and solvent materials.

Before pilot testing begins bench scale tests are performed to generate liquid-liquid equilibrium data. In addition to supplying the equilibrium data, these tests can reveal phase behavior near the liquid-liquid interface such as emulsification or entrainment that help guide extractor selection.

Tiei Extraction focus on being Mixing And Separation Solution Provider