Client: Malaysia XXX university

Application: Rare earth extraction and separation research

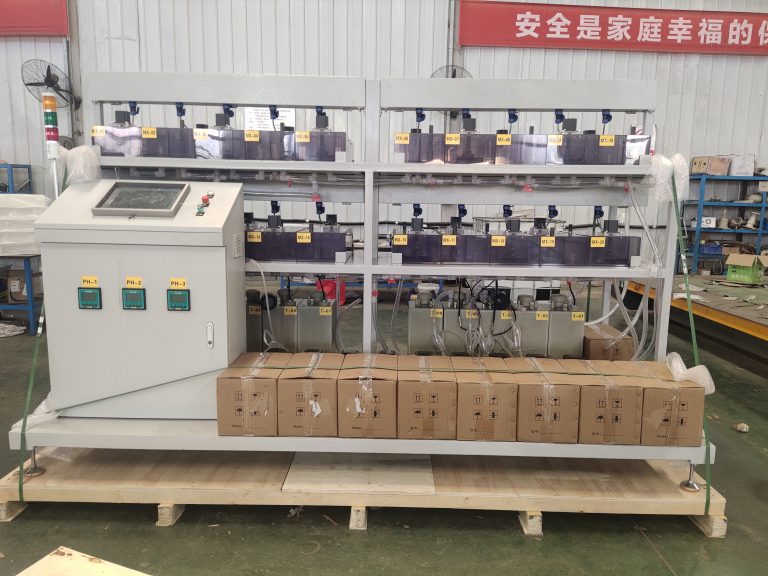

Number: 30 stages

Technology: provided by client

Customization: Yes

Construction unit: A university in Malaysia

Production time: 2023

Main machine selection: Lab Mixer Settler

Mixed flux: 18L/H

Client: Malaysia XXX university

Application: Rare earth extraction and separation research

Number: 30 stages

Technology: provided by client

Customization: Yes

This project is for one of the University in Malaysia.

Our mixer settler is the first solvent extraction equipment in Malaysia which used for research the Rare Earth Separation.

We customized this mixer settler unit for our client according to the technical flow.

REE means Rare earth elements. It is a collective term for seventeen metallic elements in the periodic table, including lanthanide elements and scandium and yttrium. There are 250 types of rare earth minerals in nature

According to the atomic electronic layer structure and physicochemical properties of rare earth elements, as well as their symbiotic situation in minerals and the characteristics that different ion radii can produce different properties, seventeen rare earth elements are usually divided into two groups:

Classification by extraction and separation:

Today we will talk about the extraction and separation of Rare Earth Elements by Solvent Extraction.

The method of using organic solvents to extract and separate the extracted substance from an immiscible aqueous solution is called organic solvent liquid-liquid extraction method, abbreviated as solvent extraction method. It is a mass transfer process that transfers substances from one liquid phase to another. Solvent extraction technology can efficiently and quickly achieve the separation and enrichment of rare earth elements, and is widely used in the extraction, purification, and separation processes of rare earth elements.

The extraction process can generally be divided into three main stages: extraction, washing, and stripping.

The equipment we used for REE extraction and separation is mainly centrifugal extractor or mixer settler.

Three typical extractants we used for REE extraction and separation:

These extractants have high viscosity and specific gravity, making them difficult to separate from water. It is usually diluted with kerosene before use.

The application of solvent extraction in rare earth element separation mainly includes the following aspects:

Rare Earth is the National Strategic Resources of each country.

Our technology is prohibited to use in other countries.

If you want to do REE extraction and separation, you need to find our your own technology.

So the lab mixer settler or centrifugal extractor must be the first step.

Tiei extraction recommend LABORATORY EXTRACTION EQUIPMENT, to help you understand the extraction equipment, to verify technolgoy process and equipment characteristics.

Also you can view relevant CUSTOMER CASES, EXTRACTION EQUIPMENT SOLUTIONS and RESEARCH TRENDS and browse all extraction equipment.

Leave your questions and we will get in touch with you as soon as possible

Leave your questions and we will get in touch with you as soon as possible